A good SMT paste process

BackA good SMT paste process

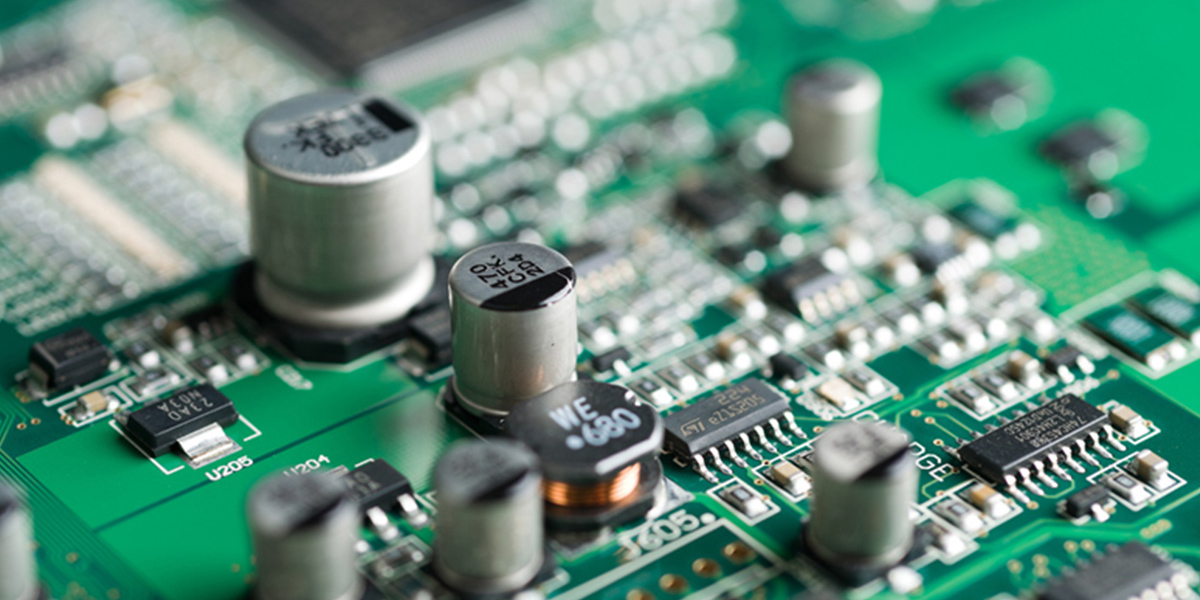

Cimar Electronics cooperates with leading suppliers in order to ensure a good quality. It definitely goes for our supplier of solder pastes and screens. After all, various researches have shown that 50% of the possible soldering defects are a result of this first step in the SMT production process.

Results print assembly predictable

Goal is to minimize the number of defects at this stage. Our supplier Rotec offers a combined solution. Thanks to extensive research to the interaction between screen and paste, these two products have been perfectly fine-tuned, allowing print assembly results to become predictable.

One of the results of these researches is that screen thickness can be determined based on a mathematic model. Small components won’t get too much soldering paste, yet larger components will get enough. It is even possible to process several thicknesses in the same screen, for example if a sensitive connector needs more soldering paste compared to the rest of the components on the PCB.

High accuracy screen

For most outsiders, a screen simply looks like a metal place with holes, but actually it is a unique tool designed by a trained team of CAD-engineers, according to design rules that have an impact on:

- Optimizing BGA design rules, especially for fine pitch BGA’s

- Avoiding fasteners at fine pitch connectors and QFP’s

- Avoiding soldering balls at passive components

- Anti-tombstone design

- Optimized QFN-design

To get an impression of the high accuracy of such a screen:

By means of 6 sigma optimization of the climatized laser accuracies of 3-5 (!) micron can be achieved on a cut screen hole.

More news

About Cimar Electronics

About us Cimar Electronics stands for launching your product together. Since 1990 we, as specialist, have been challenged continuou... Read moreContact us

We are gladly to discuss the possibilities with you. Call for more information or an appointment, 0318 - 550 545 or use our contact form ContactA good SMT paste process

Cimar Electronics cooperates with leading suppliers in order to ensure a good quality. It definitely goes for our supplier of solder pastes and screens. After all, various researches have shown that 50% of the possible soldering defects are a result of this first step in the SMT production process.

Results print assembly predictable

Goal is to minimize the number of defects at this stage. Our supplier Rotec offers a combined solution. Thanks to extensive research to the interaction between screen and paste, these two products have been perfectly fine-tuned, allowing print assembly results to become predictable.

One of the results of these researches is that screen thickness can be determined based on a mathematic model. Small components won’t get too much soldering paste, yet larger components will get enough. It is even possible to process several thicknesses in the same screen, for example if a sensitive connector needs more soldering paste compared to the rest of the components on the PCB.

High accuracy screen

For most outsiders, a screen simply looks like a metal place with holes, but actually it is a unique tool designed by a trained team of CAD-engineers, according to design rules that have an impact on:

- Optimizing BGA design rules, especially for fine pitch BGA’s

- Avoiding fasteners at fine pitch connectors and QFP’s

- Avoiding soldering balls at passive components

- Anti-tombstone design

- Optimized QFN-design

To get an impression of the high accuracy of such a screen:

By means of 6 sigma optimization of the climatized laser accuracies of 3-5 (!) micron can be achieved on a cut screen hole.

More news

-

Acquisition of Sense-WARE Fire and Gas De...

Acquisition of Sense-WARE Fire and Gas De...

-

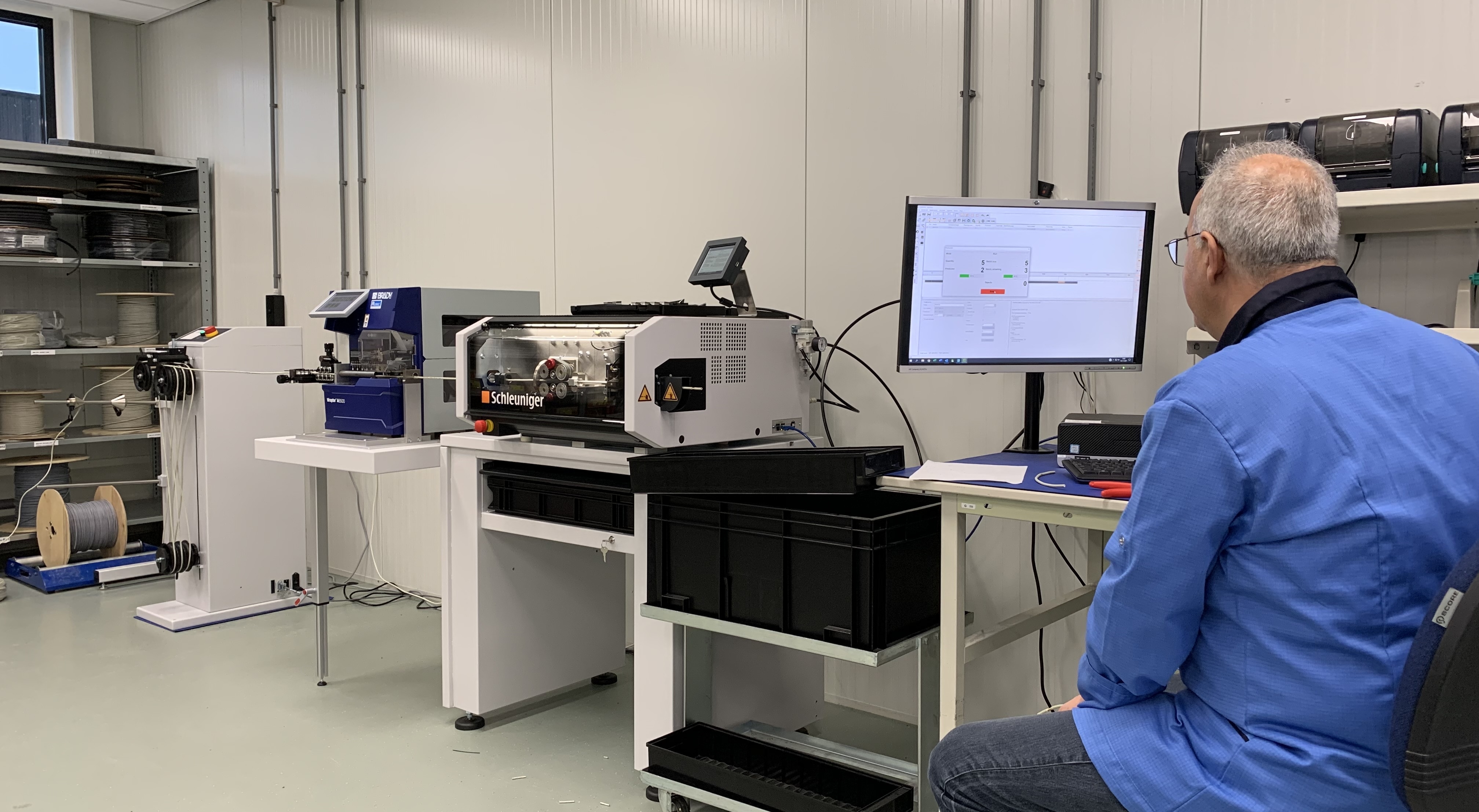

New production line for cable assembly

New production line for cable assembly

-

Testing of crimp joints

Testing of crimp joints

-

Cimar Electronics wins title 'Business of...

Cimar Electronics wins title 'Business of...

-

Trip to Antwerp

Trip to Antwerp

-

Mission in Kenya

Mission in Kenya

-

Optimal traceability

Optimal traceability

-

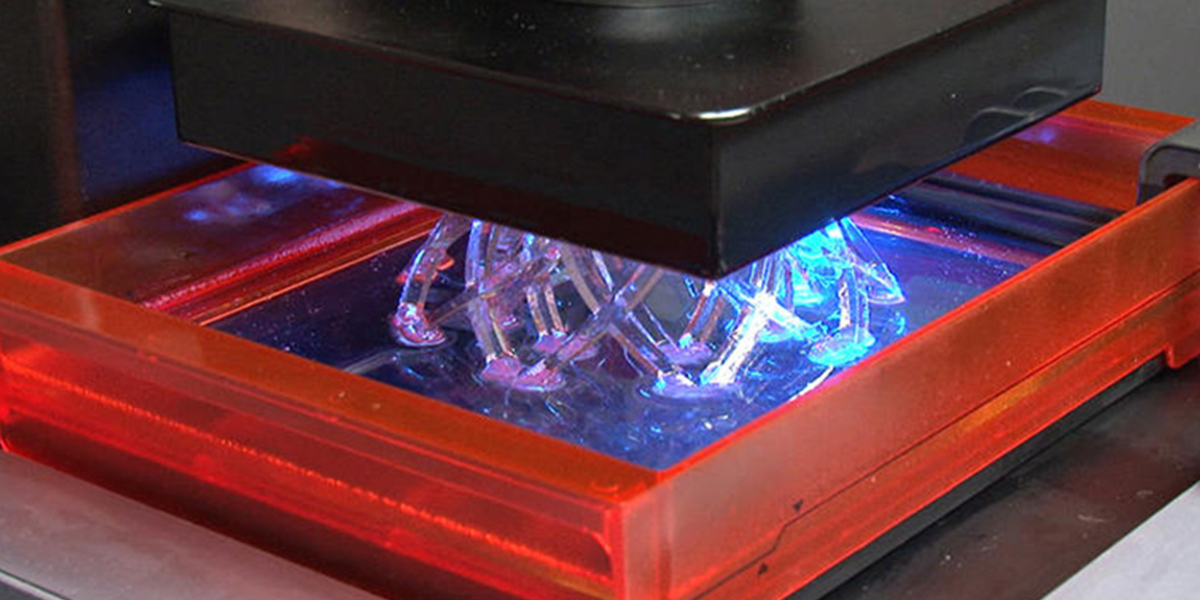

3D printing with Cimar Electronics

3D printing with Cimar Electronics

-

Cimar main sponsor SKF

Cimar main sponsor SKF

-

Exchange capacity

Exchange capacity

-

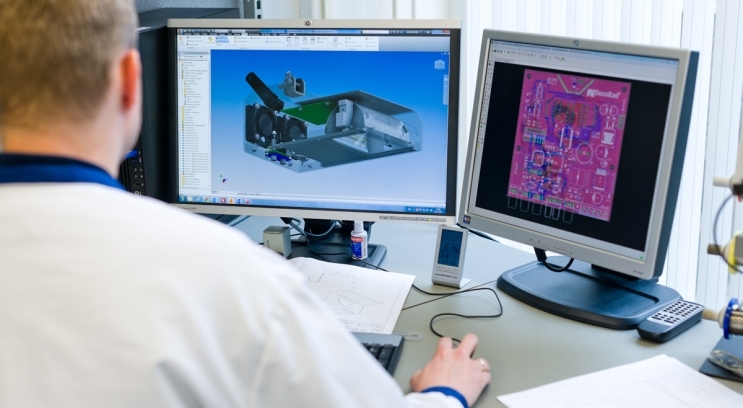

Efficiency by 3D- software

Efficiency by 3D- software