Testing of crimp joints

BackTesting of crimp joints

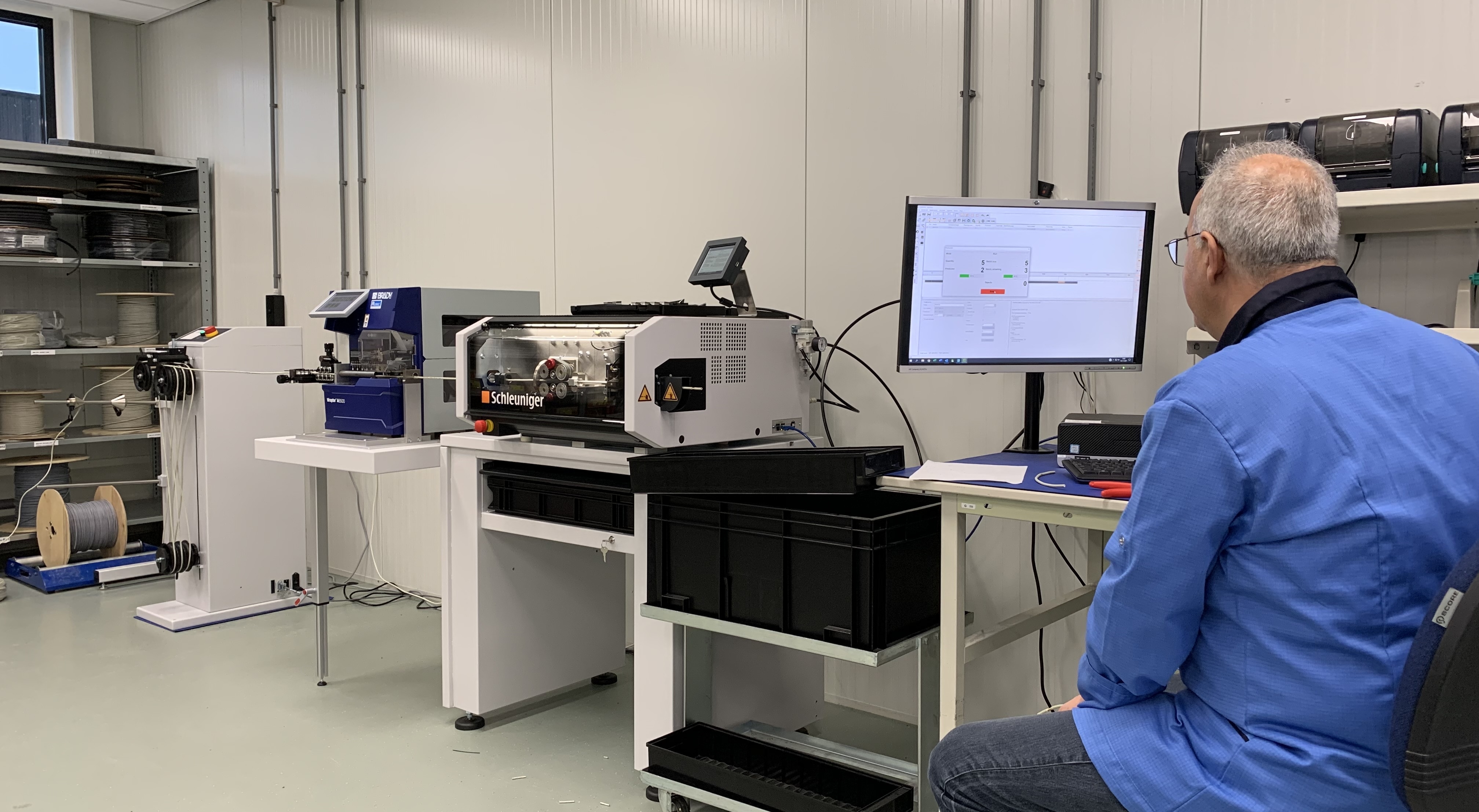

Cimar manufactures all kinds of wiring and cabling for various applications and sectors, including the entertainment, health care and automotive sectors. The automotive industry has very strict requirements when it comes to reliable and high-quality connections. That applies to us as a wholesaler, but certainly also to you as a retailer. Crimping is used to make a solid electrical connection: the crimp is deformed with a crimping tool in such a way that the crimp continues to press on the compressed wire like a spring.

There are a number of things that are crucial when making a good crimp joint:

- Apply the correct crimp contact according to the thickness of the core and the insulation of the wiring

- Applying the correct stripping length

- Using a calibrated crimping tool appropriate for the type of crimp contact

The requirements to be met by the product and the crimp joints are determined before large-scale production takes place. This makes it clear what the product (prototype) needs to be tested for and when the tests are successful. The defined process and material are tested on the prototype according to plan in order to approve the applied crimp joint:

- A visual inspection (clamping on the core and on the insulation)

- Checking the correct crimp height with a micrometre

- Testing the strength of crimp joints by tensile testing (destructive test)

Only after approval of this test on the prototype will the actual production numbers be manufactured. This way, we can be sure that the crimp joints used in all final products meet all requirements!

More news

About Cimar Electronics

About us Cimar Electronics stands for launching your product together. Since 1990 we, as specialist, have been challenged continuou... Read moreContact us

We are gladly to discuss the possibilities with you. Call for more information or an appointment, 0318 - 550 545 or use our contact form ContactTesting of crimp joints

Cimar manufactures all kinds of wiring and cabling for various applications and sectors, including the entertainment, health care and automotive sectors. The automotive industry has very strict requirements when it comes to reliable and high-quality connections. That applies to us as a wholesaler, but certainly also to you as a retailer. Crimping is used to make a solid electrical connection: the crimp is deformed with a crimping tool in such a way that the crimp continues to press on the compressed wire like a spring.

There are a number of things that are crucial when making a good crimp joint:

- Apply the correct crimp contact according to the thickness of the core and the insulation of the wiring

- Applying the correct stripping length

- Using a calibrated crimping tool appropriate for the type of crimp contact

The requirements to be met by the product and the crimp joints are determined before large-scale production takes place. This makes it clear what the product (prototype) needs to be tested for and when the tests are successful. The defined process and material are tested on the prototype according to plan in order to approve the applied crimp joint:

- A visual inspection (clamping on the core and on the insulation)

- Checking the correct crimp height with a micrometre

- Testing the strength of crimp joints by tensile testing (destructive test)

Only after approval of this test on the prototype will the actual production numbers be manufactured. This way, we can be sure that the crimp joints used in all final products meet all requirements!

More news

-

Acquisition of Sense-WARE Fire and Gas De...

Acquisition of Sense-WARE Fire and Gas De...

-

New production line for cable assembly

New production line for cable assembly

-

Cimar Electronics wins title 'Business of...

Cimar Electronics wins title 'Business of...

-

Trip to Antwerp

Trip to Antwerp

-

Mission in Kenya

Mission in Kenya

-

Optimal traceability

Optimal traceability

-

A good SMT paste process

A good SMT paste process

-

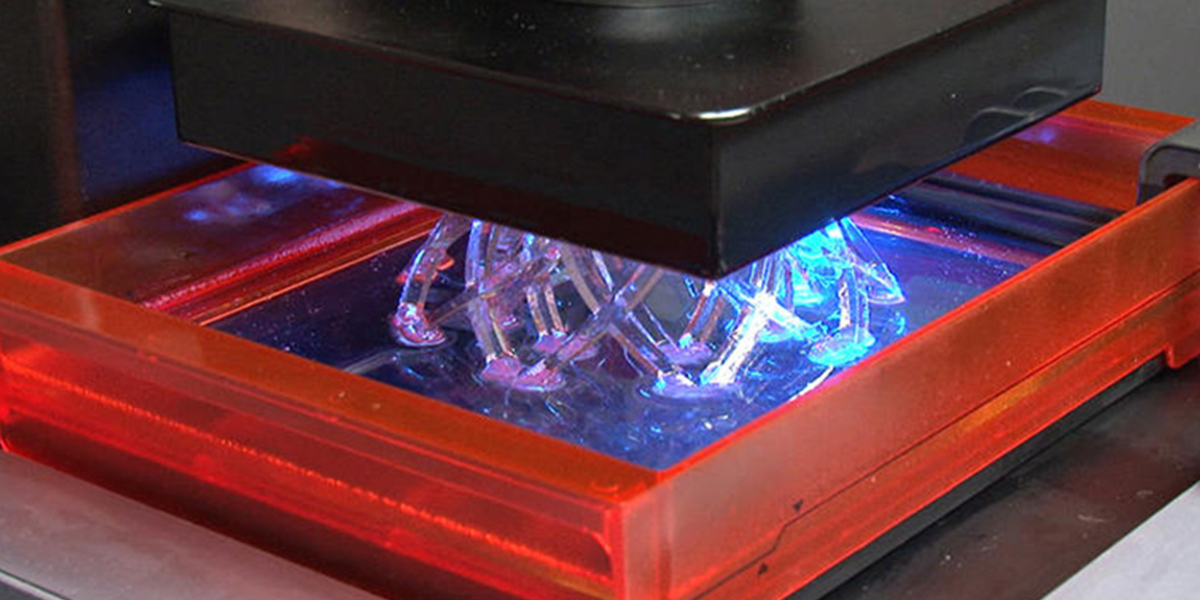

3D printing with Cimar Electronics

3D printing with Cimar Electronics

-

Cimar main sponsor SKF

Cimar main sponsor SKF

-

Exchange capacity

Exchange capacity

-

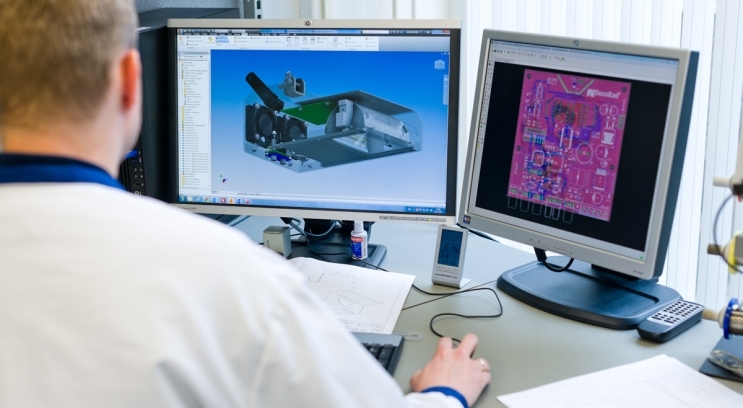

Efficiency by 3D- software

Efficiency by 3D- software