New production line for cable assembly

BackNew production line for cable assembly

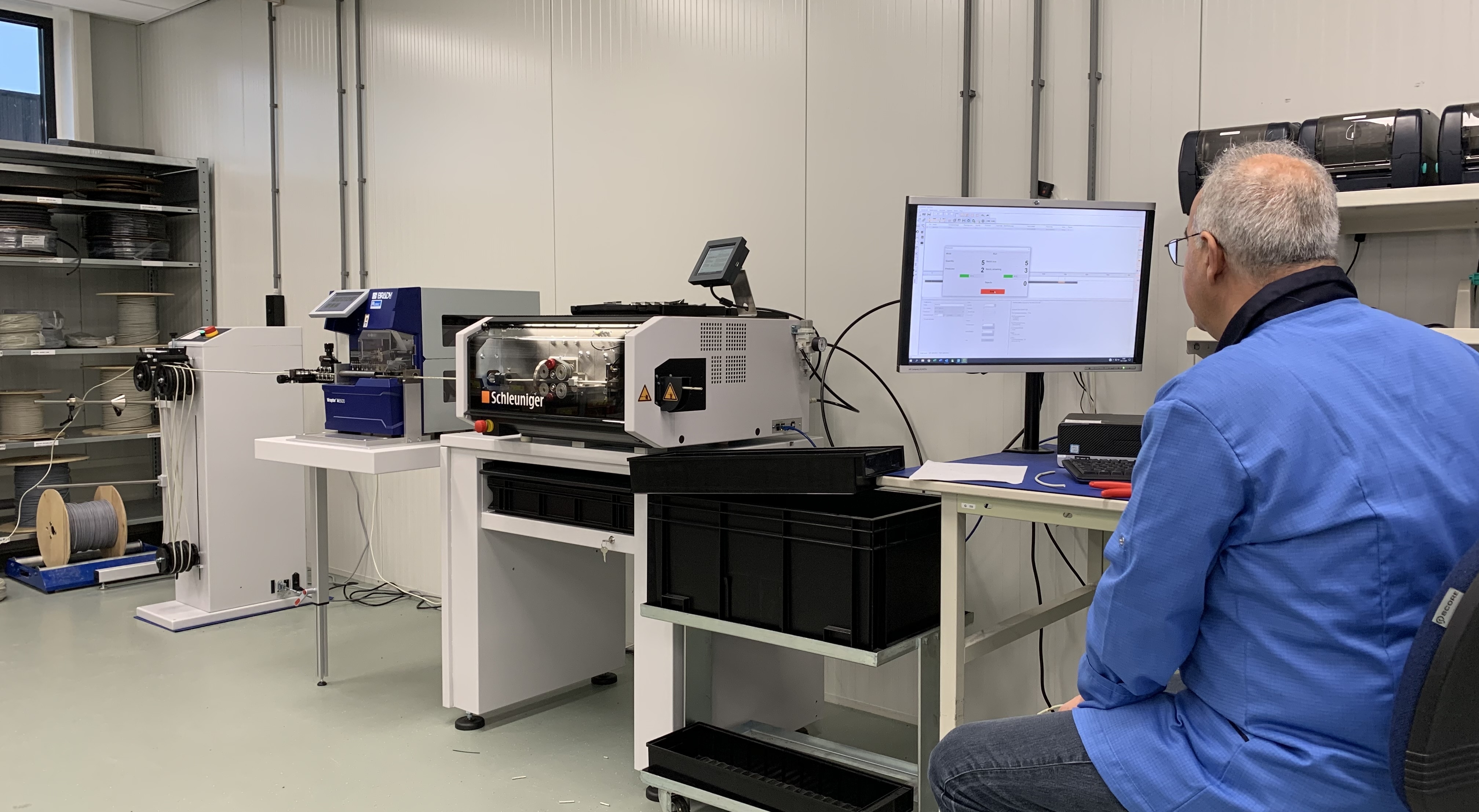

Cimar recently commissioned a new Schleuniger cutting & stripping machine. This fully automated production line now allows us to cut, strip, dismantle and label cables and wires to the requested lengths directly from the spool. The new production line is the perfect addition to our cable assembly department and guarantees an efficient and customer-specific cable and wire production of consistent quality.

The production line consists of 3 main elements:

1 - a prefeeding machine to feed cables and wires from spools up to 70(!) kg to the cable cutting and stripping machine. This universal and free-standing machine lets us very meticulously set the cable entry speed to ensure that this consistently matches the demand of the “receiving” machine.

2 - a fully automated cable stripper and cutter that offers a high production output with huge and consistent precision. This machine is one of the most versatile cutting & stripping machines available.

3 - An advanced label printer to correctly label the cables and wires. The label printer prints the matching labels and wraps them around a cable or wire in just seconds. This innovative printing and application system combines a series of labour-intensive steps into one fast and fully automated process.

The new production line enables Cimar to carry out different automated processes to produce customer-specific cables and wires. Furthermore, Cimar now also has the monitoring and inspection equipment on-site to optimally guarantee the quality during the entire production process.

More news

About Cimar Electronics

About us Cimar Electronics stands for launching your product together. Since 1990 we, as specialist, have been challenged continuou... Read moreContact us

We are gladly to discuss the possibilities with you. Call for more information or an appointment, 0318 - 550 545 or use our contact form ContactNew production line for cable assembly

Cimar recently commissioned a new Schleuniger cutting & stripping machine. This fully automated production line now allows us to cut, strip, dismantle and label cables and wires to the requested lengths directly from the spool. The new production line is the perfect addition to our cable assembly department and guarantees an efficient and customer-specific cable and wire production of consistent quality.

The production line consists of 3 main elements:

1 - a prefeeding machine to feed cables and wires from spools up to 70(!) kg to the cable cutting and stripping machine. This universal and free-standing machine lets us very meticulously set the cable entry speed to ensure that this consistently matches the demand of the “receiving” machine.

2 - a fully automated cable stripper and cutter that offers a high production output with huge and consistent precision. This machine is one of the most versatile cutting & stripping machines available.

3 - An advanced label printer to correctly label the cables and wires. The label printer prints the matching labels and wraps them around a cable or wire in just seconds. This innovative printing and application system combines a series of labour-intensive steps into one fast and fully automated process.

The new production line enables Cimar to carry out different automated processes to produce customer-specific cables and wires. Furthermore, Cimar now also has the monitoring and inspection equipment on-site to optimally guarantee the quality during the entire production process.