Optimal traceability

BackOptimal traceability

Early 2016, we started with the further digitisation of the work processes and this new work method has now been largely implemented. The principles of this and the advantages for the client are:

- Optimal traceability of components and products

- The option of trend analyses to reduce error margins

- An even more efficient and faster work process; such as the option to immediately and digitally implement adjustments or updates in a product

After meeting all the wishes and requirements, the right software has been found. Within Cimar Electronics, this project was set up by SMT production employee Hend Dekker and work planner Jan Teunis Pol. The new work method was first introduced in the SMT department. After several tests with various products, all lessons learned have been processed. The implementation is now realised at the other departments and it is expected that this will be completed in the second quarter of 2017.

QR codes

All products are given QR codes. During the process, every product must be scanned and can only be further processed after the correct updates have been implemented. The acquired data helps to limit possible mistakes and ensure optimal traceability. They also help to inform clients better about the actual status of the production and the expected lead time.

Would you like to know more?

Would you like to know more about how we apply this work method for your product, or do you have any other questions? Please do not hesitate to contact us!

More news

About Cimar Electronics

About us Cimar Electronics stands for launching your product together. Since 1990 we, as specialist, have been challenged continuou... Read moreContact us

We are gladly to discuss the possibilities with you. Call for more information or an appointment, 0318 - 550 545 or use our contact form ContactOptimal traceability

Early 2016, we started with the further digitisation of the work processes and this new work method has now been largely implemented. The principles of this and the advantages for the client are:

- Optimal traceability of components and products

- The option of trend analyses to reduce error margins

- An even more efficient and faster work process; such as the option to immediately and digitally implement adjustments or updates in a product

After meeting all the wishes and requirements, the right software has been found. Within Cimar Electronics, this project was set up by SMT production employee Hend Dekker and work planner Jan Teunis Pol. The new work method was first introduced in the SMT department. After several tests with various products, all lessons learned have been processed. The implementation is now realised at the other departments and it is expected that this will be completed in the second quarter of 2017.

QR codes

All products are given QR codes. During the process, every product must be scanned and can only be further processed after the correct updates have been implemented. The acquired data helps to limit possible mistakes and ensure optimal traceability. They also help to inform clients better about the actual status of the production and the expected lead time.

Would you like to know more?

Would you like to know more about how we apply this work method for your product, or do you have any other questions? Please do not hesitate to contact us!

More news

-

Acquisition of Sense-WARE Fire and Gas De...

Acquisition of Sense-WARE Fire and Gas De...

-

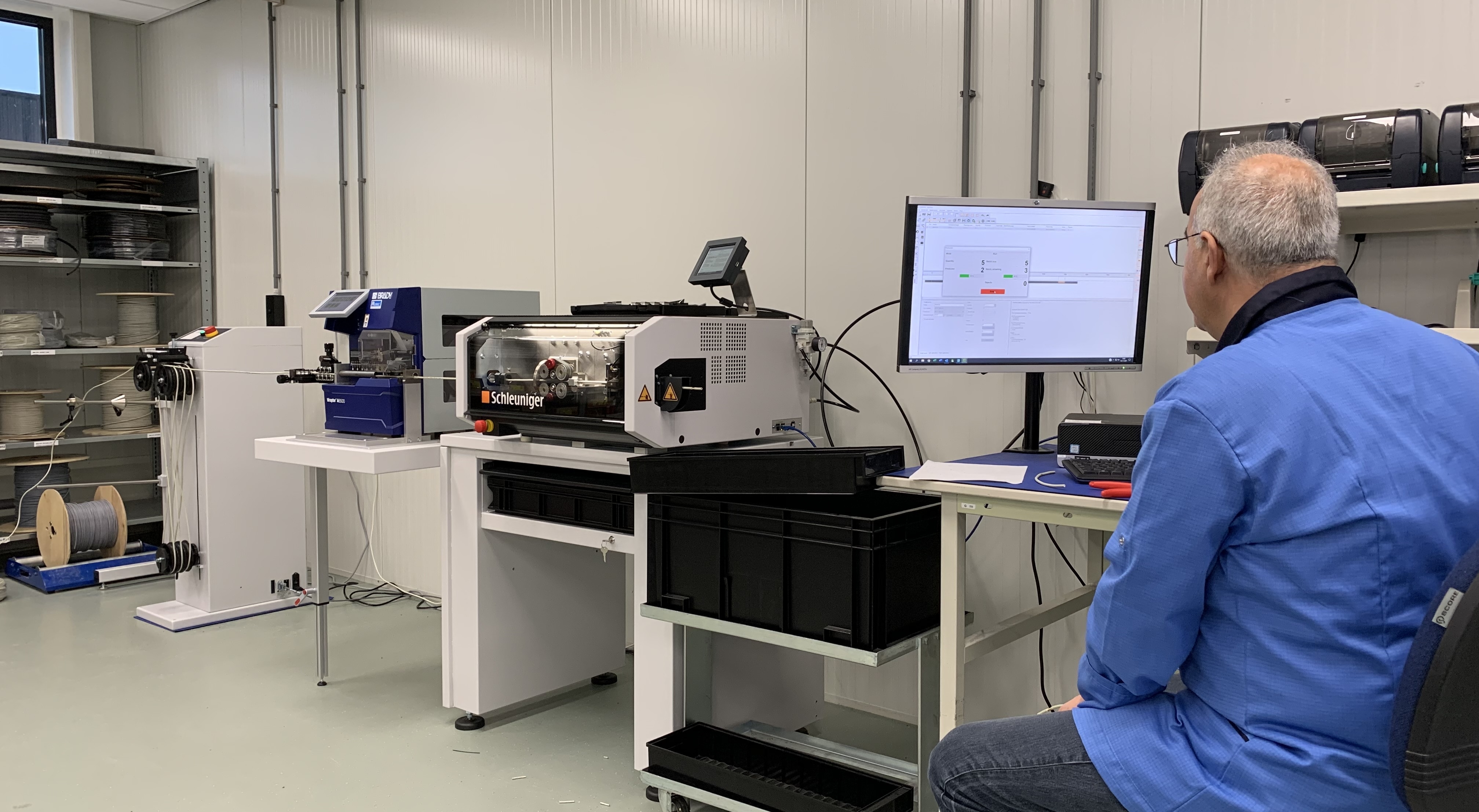

New production line for cable assembly

New production line for cable assembly

-

Testing of crimp joints

Testing of crimp joints

-

Cimar Electronics wins title 'Business of...

Cimar Electronics wins title 'Business of...

-

Trip to Antwerp

Trip to Antwerp

-

Mission in Kenya

Mission in Kenya

-

A good SMT paste process

A good SMT paste process

-

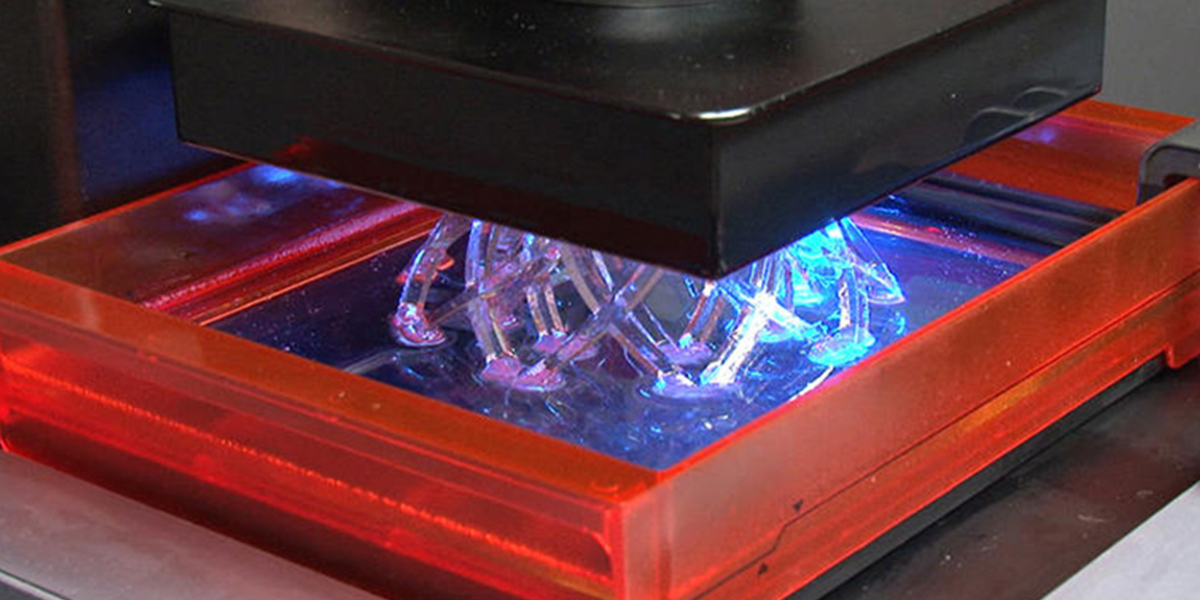

3D printing with Cimar Electronics

3D printing with Cimar Electronics

-

Cimar main sponsor SKF

Cimar main sponsor SKF

-

Exchange capacity

Exchange capacity

-

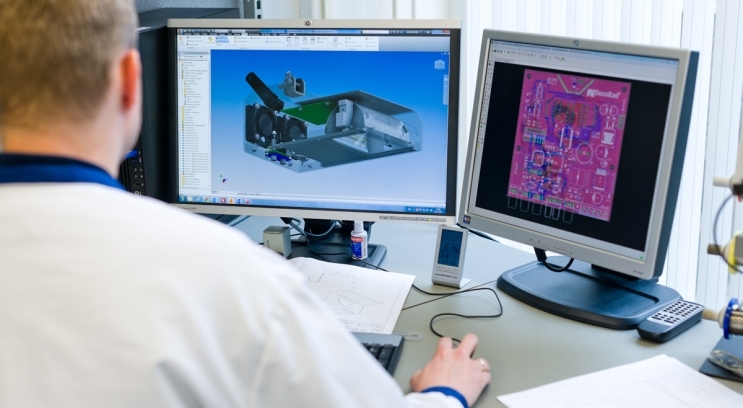

Efficiency by 3D- software

Efficiency by 3D- software